Pipe Gallery Robot Monitoring System是一种用于监控管道机器人系统的软件应用。它能够实时监控机器人的运行状态,包括位置、速度、方向等,确保机器人按照预定的任务进行工作。它还能对机器人的电量、温度、湿度等参数进行监测,确保机器人的安全运行。Pipe Gallery Robot Monitoring System还能对机器人的故障进行诊断和处理,保证机器人的稳定运行。,,通过Pipe Gallery Robot Monitoring System,操作人员可以实时了解机器人的运行状态,及时调整机器人的任务安排,确保机器人的高效运行。它还能减少人工监控的成本和时间,提高管道机器人的运行效率。Pipe Gallery Robot Monitoring System在管道机器人系统中扮演着重要的角色,确保了管道机器人的稳定运行和高效管理。

In today's world, technology has become an integral part of various industries, including the construction and management of pipe galleries. To ensure the efficient and safe operation of these systems, it is crucial to have a reliable monitoring system in place. This article will introduce you to the Pipe Gallery Robot Monitoring System, which offers a cutting-edge solution for monitoring and managing your pipe gallery system.

What is a Pipe Gallery Robot Monitoring System?

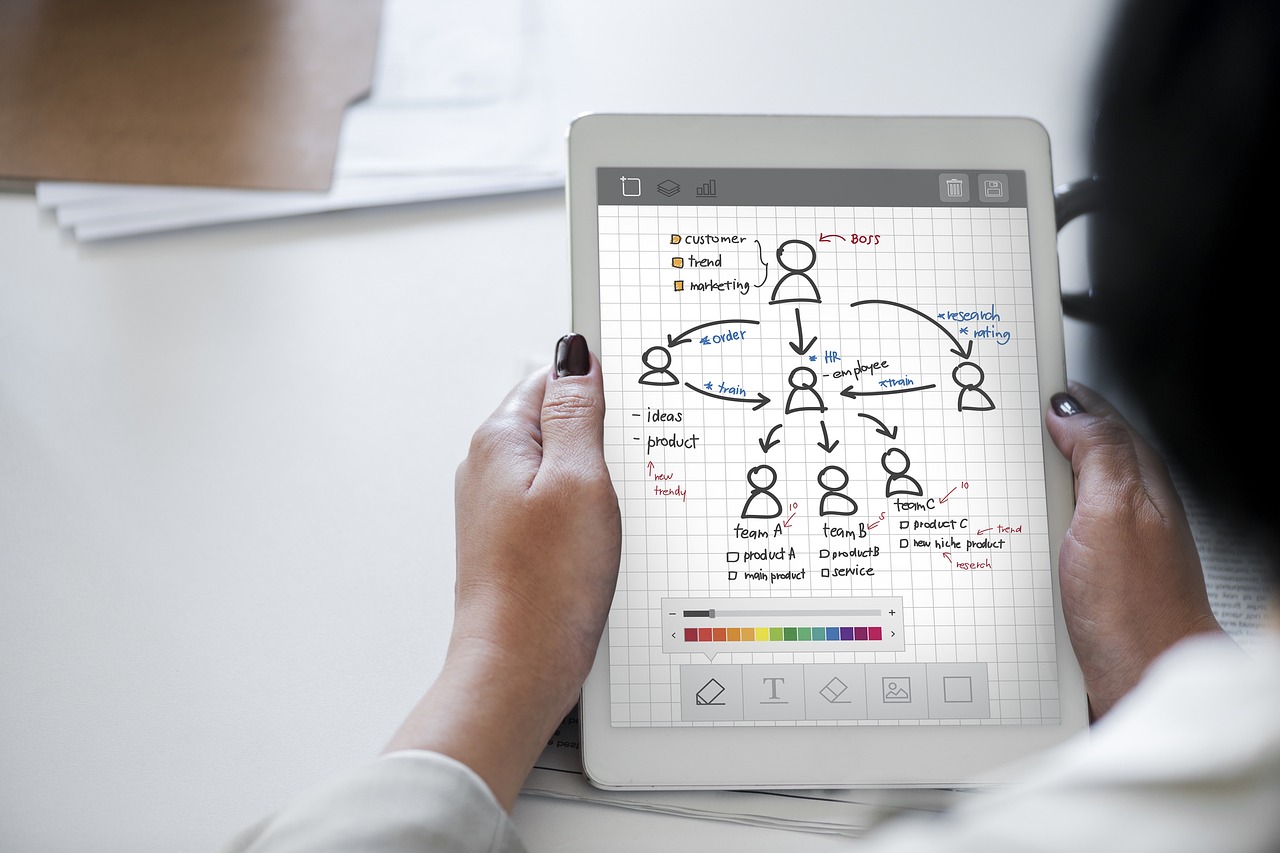

A Pipe Gallery Robot Monitoring System is an advanced technology that allows for the remote monitoring and management of pipe gallery systems. This system utilizes robots equipped with sensors and cameras to traverse the length of the pipe gallery, capturing real-time data and images that are then transmitted to a central monitoring station. From this station, operators can monitor the entire system, identify potential issues, and take appropriate action to ensure the system's smooth and safe operation.

How does a Pipe Gallery Robot Monitoring System work?

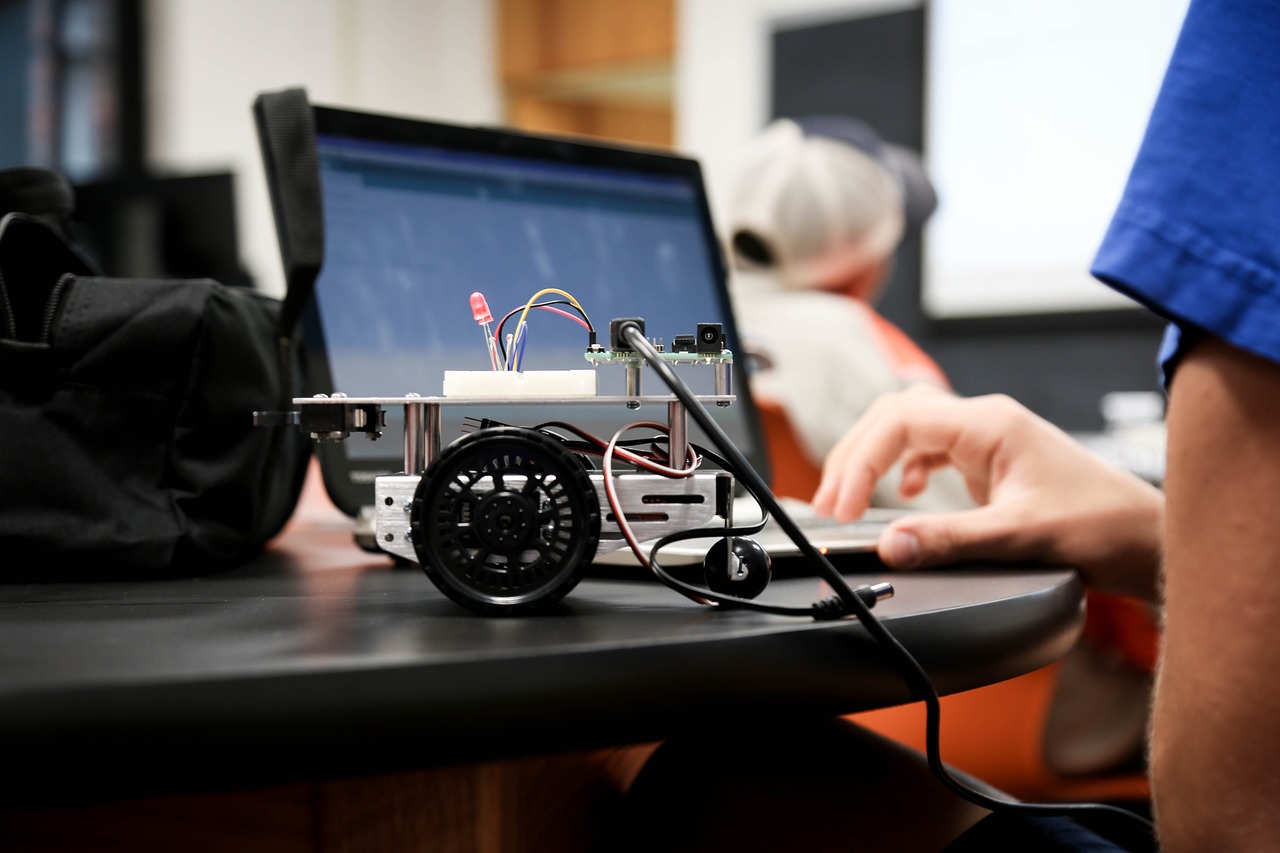

The Pipe Gallery Robot Monitoring System consists of several key components, including the robots themselves, the sensors and cameras, and the central monitoring station. The robots are designed to travel through the pipe gallery, following a predetermined route. As they move, they capture real-time data on various parameters, such as temperature, pressure, and flow rates. This data is then transmitted to the central monitoring station, where it is analyzed and displayed in a user-friendly interface.

The sensors and cameras on the robots provide additional functionality. They can detect any abnormalities or potential issues within the system, such as leaks or blockages. This information is also sent to the monitoring station, allowing operators to take preventive measures or address any concerns immediately.

What are the benefits of a Pipe Gallery Robot Monitoring System?

There are numerous benefits associated with implementing a Pipe Gallery Robot Monitoring System in your pipe gallery system. Firstly, it significantly enhances the efficiency of monitoring and management. By automating data collection and analysis, operators can reduce their workload and improve the accuracy of data-driven decisions. Additionally, it allows for remote monitoring, meaning that operators can access the system anytime, anywhere, significantly increasing their flexibility and productivity.

Secondly, a Pipe Gallery Robot Monitoring System improves system safety. By continuously monitoring system parameters and detecting potential issues, it helps to prevent accidents or incidents that could compromise the integrity of the system or pose a risk to personnel. Furthermore, it can also help to identify and address any environmental concerns related to the system's operation.

Thirdly, it enhances system reliability. By providing continuous monitoring and data analysis, it helps to identify and correct any issues that could affect system performance or stability. This ensures that your pipe gallery system operates at its peak performance level, reducing any downtime or maintenance costs associated with its operation.

In conclusion, a Pipe Gallery Robot Monitoring System offers a cutting-edge solution for monitoring and managing your pipe gallery system. By automating data collection and analysis, improving system safety and reliability, it helps to ensure the efficient and smooth operation of your system while reducing any potential risks or concerns. As technology continues to evolve and develop new solutions for industrial applications like these ones mentioned here today - we can only imagine what tomorrow will bring!

与本文内容相关的文章: